Food Cost Management Software

FlexiBake’s food costing software gives manufacturers, bakeries, commissaries, and restaurants precise control over ingredient expenses, labor costs, and overhead. With the right recipe costing software, businesses can protect their margins and make data-driven pricing decisions.

Whether you’re adjusting to fluctuating ingredient costs or fine-tuning menu pricing, FlexiBake provides the best food costing software to keep your business profitable.

|

Key Features of FlexiBake’s Food Costing Software

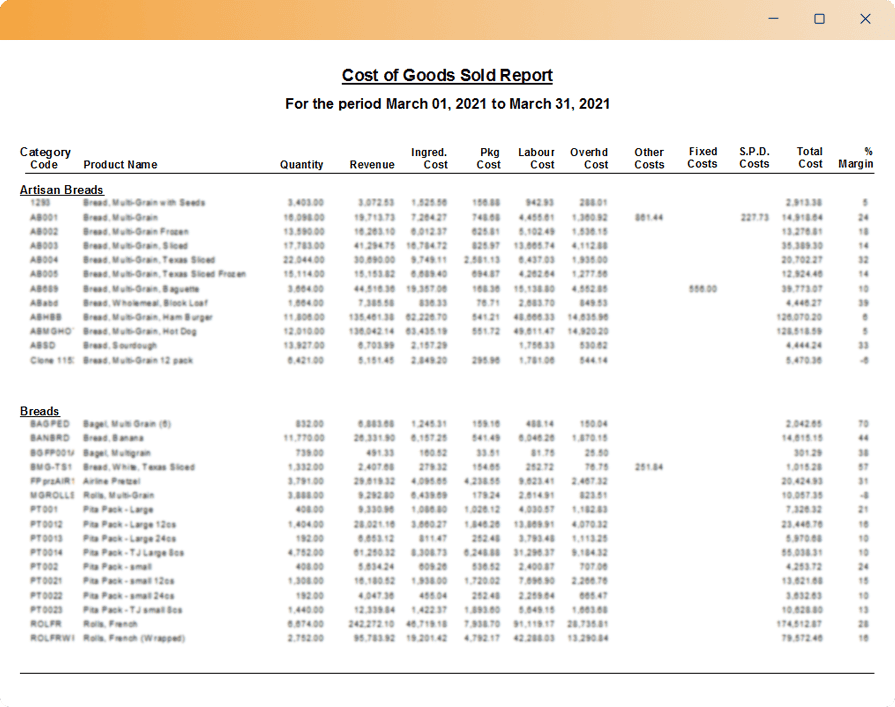

Ingredient, Labor, and Overhead Cost Tracking

Get a complete breakdown of all expenses, including ingredients, packaging, wages, utilities, and other overhead costs. Update raw material costs instantly upon receipt. Add labor burden per recipe and factor in fixed costs with a simple template. Costing reports provide a clear breakdown of the total cost per recipe. FlexiBake ensures that every dollar spent is accounted for and protects your margins.

Smarter Profit Margin Pricing

Food and beverage costing software eliminates guesswork, preventing underpricing that erodes profitability or overpricing that drives customers away. If you need a specific profit margin, let FlexiBake automatically calculate the ideal product price based on current and average material costs. Easily price products for new contracts, customers, or seasonal offerings while maintaining strong margins.

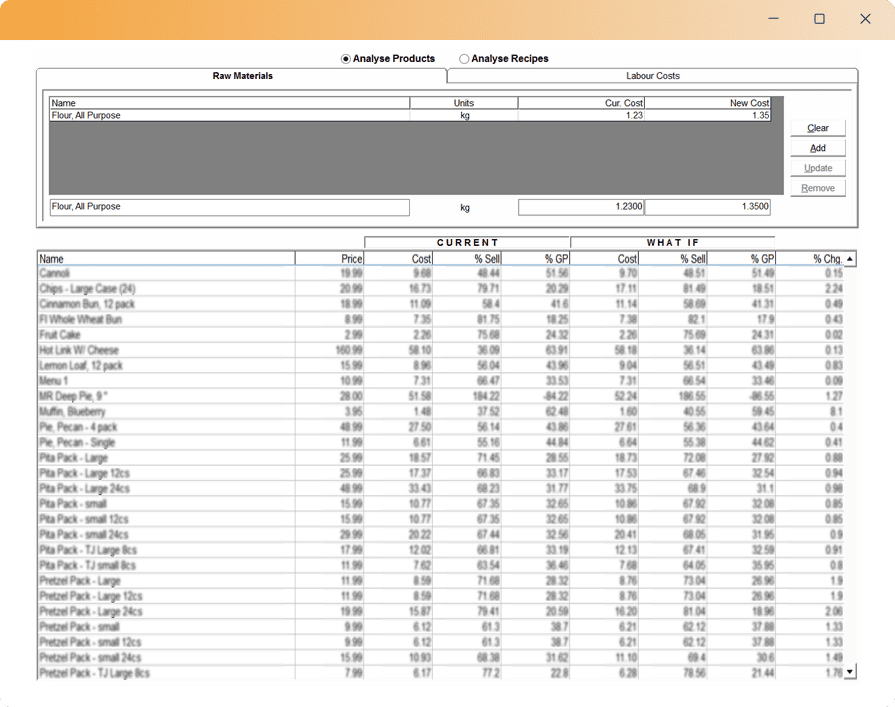

Ingredient prices fluctuate daily, and labor costs rise. FlexiBake’s food cost program tracks these changes instantly, allowing you to adjust recipes, switch suppliers, or modify pricing strategies before costs get out of control.

Recipe Cost Calculation & Profit Optimization

Understanding the actual cost of every product is critical in food manufacturing. With menu costing software, you can tweak portion and batch sizes, swap ingredients, or adjust pricing—and immediately see how it impacts profitability.

By integrating FlexiBake’s food costing and inventory software, businesses gain a clear financial overview, reduce unnecessary costs, and improve long-term profitability.

“What If” Analysis Tools to Predict Costs

Create custom pricing strategies, including tiered discounts, product-based pricing, and customer-specific price tiers. Assign sales-dependent costs as a percentage of the selling price and configure company-owned locations with unique pricing rules. Costs are calculated and can be analyzed by the product or any step of the process, whether a work in progress or a base formula.

Common Cost-Related Challenges in Food Production

Running a food business isn’t just about creating great products—it’s about controlling costs while staying profitable. With rising ingredient prices, increasing labor costs, and hidden inefficiencies, many businesses struggle to maintain stable margins.

Minor pricing errors can quickly add up without accurate cost tracking, cutting profits before you notice. Let’s look at the biggest cost-related challenges food manufacturers face—and why traditional cost management methods in spreadsheets aren’t enough to keep up.

Unstable Ingredient Prices

Ingredient costs are unpredictable due to supply chain disruptions, seasonal availability, and market fluctuations. Without real-time recipe costing software, businesses struggle to adjust pricing before rising costs consume profits.

Keeping Up With Rising Labor Costs

Wages continue increasing, adding pressure to tight budgets. Without clear insight into labor expenses, businesses risk underpricing or cutting into profits. Food manufacturing costing software ensures labor costs are factored into pricing.

Revenue Loss From Food Waste

Overproduction, spoilage, and inefficiencies lead to unnecessary waste. Without a clear cost breakdown, businesses may not realize how much money is lost due to mismanaged portions and expired inventory.

Poor Cost Tracking & Pricing Decisions

Many businesses use outdated spreadsheets or estimates to calculate food costs, leading to inconsistent pricing, profit loss, or overpriced products that drive customers away. Automated food costing tools help stabilize pricing, control expenses, and protect margins.

Uncover the Hidden Costs Draining Your Profits

Not all costs are visible upfront. While ingredient prices and wages are easy to track, hidden expenses—such as unnoticed price fluctuations, waste, and inefficient pricing strategies—can silently drain profits.

Many food businesses don’t realize how much money they lose until it’s too late. A 5% increase in ingredient costs might seem minor, but if pricing adjustments aren’t made in time, it can significantly reduce profitability for a year.

Are You Accounting for Every Cost Change?

Food businesses operate on razor-thin margins, where even small cost fluctuations can have a major financial impact.

Small cost increases add up fast and may seem minor, but they can quietly drain profits over thousands of units.

Seasonal pricing shifts create unseen spikes–ingredients like butter or flour fluctuate seasonally, but without tracking, businesses don’t notice until profits drop.

Freight and import fees quietly shift margins–transportation costs fluctuate due to fuel prices or tariffs, subtly increasing the actual cost of ingredients.

In recent years, ingredient and packaging costs have surged, yet many businesses fail to update pricing in time.

The Disconnect Between Costs & Pricing

Many food businesses price their products based on competitor pricing instead of actual costs.

This leads to two significant issues:

Underpricing eats away at margins and makes profitability unsustainable.

Overpricing, which pushes customers away and reduces sales.

For example, if cocoa prices jumped 150% and coffee costs reached a 15-year high, many businesses would not update their pricing accordingly. This mismatch between rising costs and stagnant pricing is a silent profit killer.

Inaccurate Data Leads to Add-On Expenses

A few unnoticed changes in ingredient prices, labor costs, or overhead expenses can snowball into major financial setbacks. Businesses relying on manual tracking often struggle with the following:

Delayed pricing adjustments, causing shrinking profit margins.

Manual data entry errors lead to incorrect financial reports and lost revenue.

Missed cost-saving opportunities simply because the correct data wasn’t available at the right time.

Some food businesses and restaurants are forced to reformulate recipes or switch to lower-cost ingredients to stay profitable. Still, even reformulation has hidden costs—new testing, packaging updates, and regulatory compliance checks can sometimes outweigh the savings.

Take Control of Your Food Costs With FlexiBake

Stop guessing and start making data-driven pricing decisions. FlexiBake’s food costing software helps you track ingredient expenses, monitor fluctuations, and protect your profit margins.

Book a free consultation to see how real-time cost tracking can keep your business profitable—no more surprises.