Lot Tracking Software

Lot tracking software empowers food manufacturers to meticulously monitor products throughout every stage of production and distribution, ensuring compliance, quality control, and operational efficiency.

Whether you need lot number tracking software for ingredient traceability or batch tracking software to streamline production, FlexiBake provides lot management software that keeps your business ahead of regulatory demands and inventory challenges.

|

Key Features of FlexiBake’s Lot Tracking System

Comprehensive Traceability

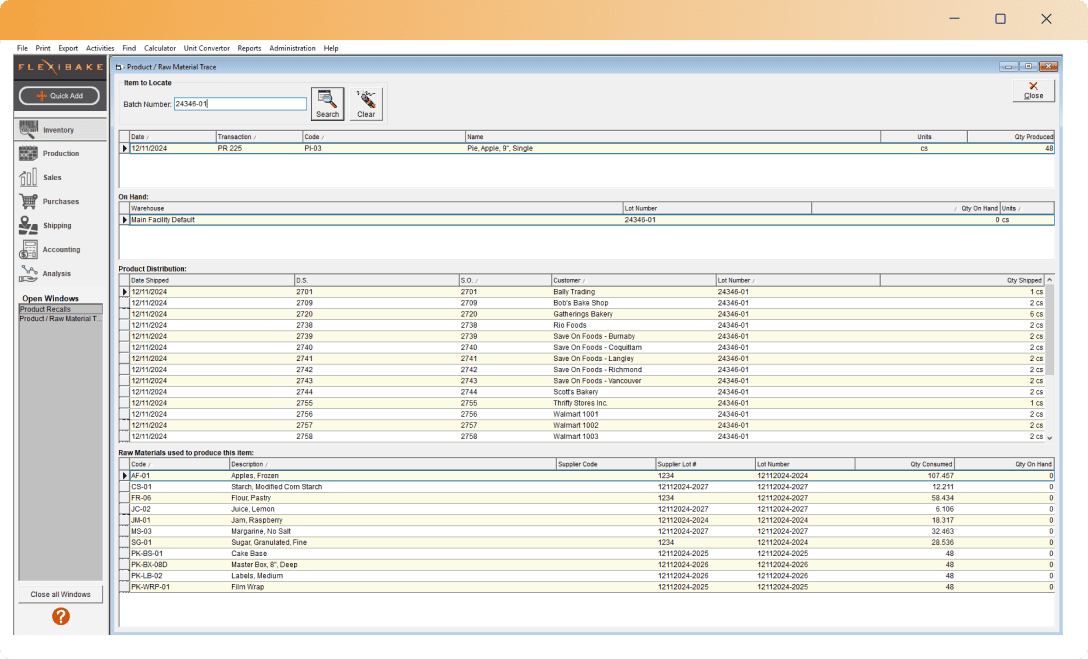

With lot traceability software, you can monitor every ingredient and finished product from receipt to dispatch, facilitating swift and efficient recalls.

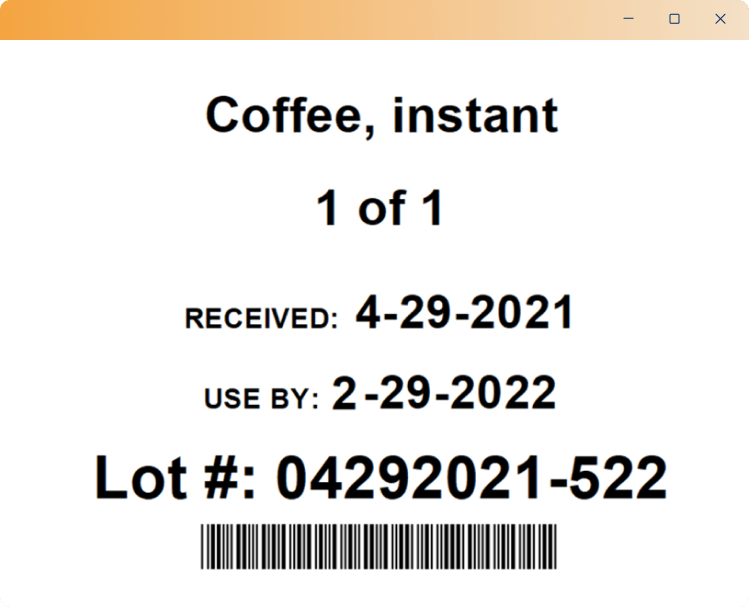

Production Support with Lot-Coded Tags

Generate lot number tracking labels for raw materials, helping production teams utilize the correct ingredients in a First-In-First-Out (FIFO) sequence—minimizing waste and errors.

Automated FIFO Management

Implement lot control software that automatically applies FIFO procedures during production and shipping while allowing flexible adjustments.

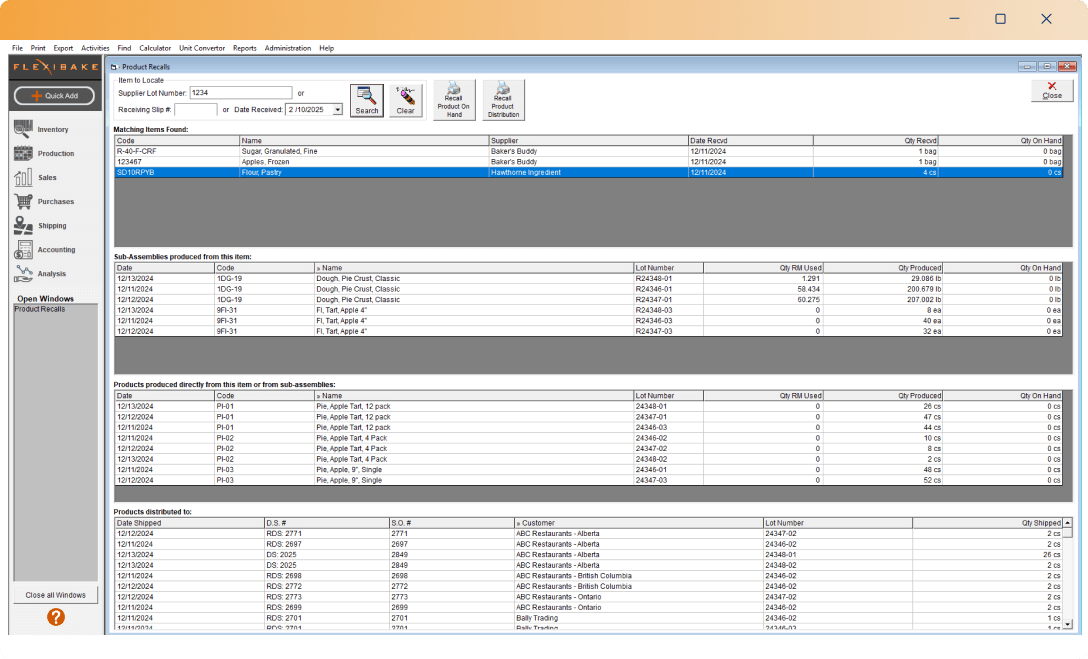

Efficient Recall Management

During a recall, lot tracking system tools quickly identify and isolate affected inventory, ensuring compliance with HACCP, FSMA, and BRC standards.

Regulatory Compliance

Maintain detailed batch tracking records to support audits and meet industry certifications like SQF, BRC, ISO, GFSI, CFIA, and USDA requirements.

By implementing FlexiBake’s lot tracking capabilities, food manufacturers

gain full transparency, reduce risks, and maintain the highest product quality standards across all departments.

Enhance Production Efficiency With Lot Tracking

Assist Production Staff With Lot-Coded Tags for Ingredients

Imagine giving your team a roadmap for ingredient management. Lot number tracking software enables production staff to accurately identify, track, and manage raw materials. These lot-coded tags streamline workflows, reduce human error, and improve operational efficiency—even during peak production.

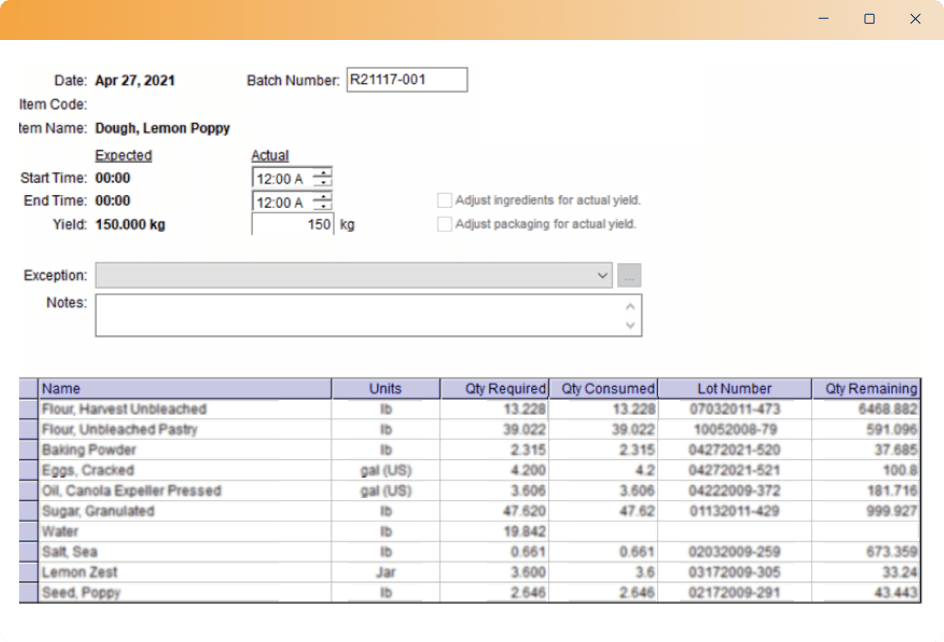

Save Time With FIFO Ingredient Consumption

No more guessing which batch to use. FlexiBake’s lot tracking software features an automated FIFO system that ensures older ingredients are used with algorithmic first-in, first-out processing, reducing spoilage and optimizing stock rotation.

Trace & Remove All Inventory to Avoid Further Contamination

In food safety, time is everything. When contamination happens, lot tracking software pinpoints the affected inventory instantly. This capability reduces risks, ensures compliance, and protects your products.

Record the Consumed Lot Code During Each Step of Production

From receiving raw materials to producing finished products, lot tracking software records every lot code, offering a transparent and complete ingredient history. This makes audits more manageable and ensures regulatory compliance.

Why Lot Tracking Matters for Food Safety

1 —

Preventing Contamination With Traceability

FlexiBake’s lot tracking system provides real-time lot number tracking, allowing manufacturers to quickly isolate contaminated ingredients and prevent further spread. Studies show that proactive traceability can reduce the scope of food recalls by up to 95%, minimizing financial and reputational damage.

2 —

Meeting Regulatory Standards

Food safety regulations—including HACCP, FSMA, and ISO 22000—require detailed tracking of all Critical Tracking Events (CTEs) and Key Data Elements (KDEs). Lot traceability software automates this process, ensuring compliance with CFIA, FDA, and USDA regulations while simplifying audits.

3 —

Simplifying Recall Management

Without proper tracking, a product recall can be catastrophic. FlexiBake’s lot control software enables businesses to trace issues upstream and downstream, and conduct product recalls in less than 10 seconds, allowing for swift inventory isolation and regulatory reporting.

4 —

Building Consumer Trust

Transparency in food production matters. 73% of consumers prioritize lot traceability when choosing food brands. Lot number tracking software enhances trust by providing detailed, verifiable records—helping businesses prove their commitment to quality and safety.

Common Business Challenges Solved by Lot Tracking

Reducing Waste

and Errors

Manual inventory tracking leads to expired stock and costly mistakes. Lot tracking software automates FIFO ingredient rotation, ensuring materials are used efficiently, preventing waste, and optimizing costs.

Managing Complex Recalls

If not handled properly, recalls can damage a brand and cost millions. Lot management software provides detailed tracking records, allowing businesses to quickly isolate affected batches and reduce the impact of recalls.

Maintaining Quality

Across Batches

Consistency is key in food production. Lot tracking software ensures every batch meets the same high standards by tracking ingredient origins, production conditions, and quality control measures.

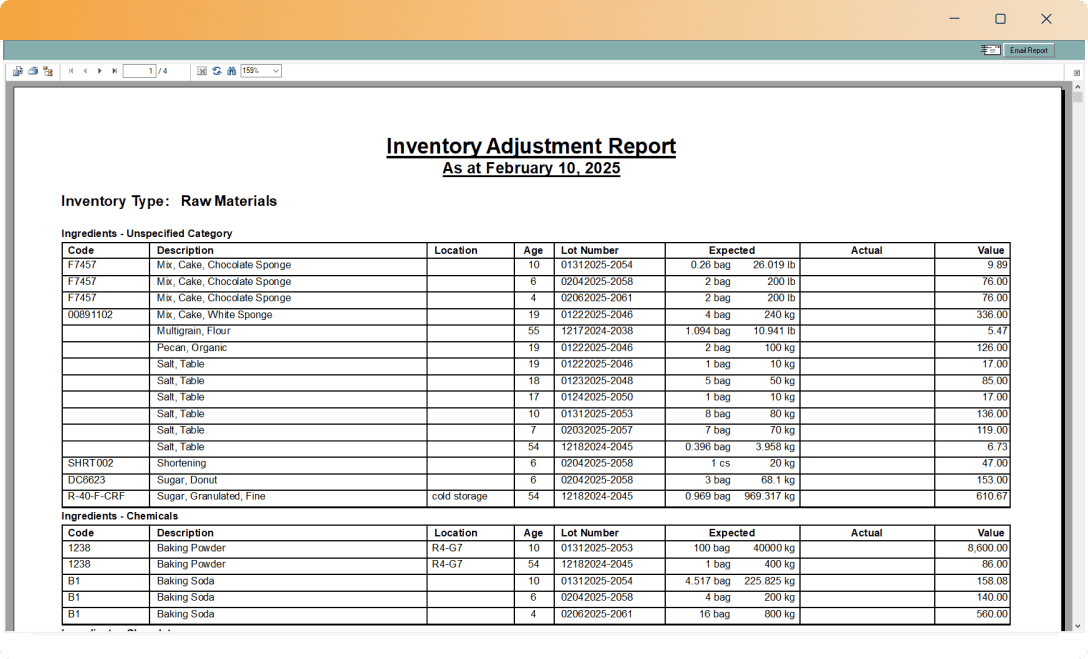

How Lot Tracking Powers Inventory Management

Maintain detailed batch tracking records to support audits and meet industry certifications like SQF, BRC, ISO, GFSI, CFIA, and USDA requirements.

Linking Lot Codes

to Stock Levels

Lot number tracking software connects each ingredient and finished product to its stock level, giving a real-time, accurate inventory overview.

Improving Inventory

Accuracy

Lot tracking system automation ensures accurate stock updates whenever materials are received, used, or shipped, reducing manual errors.

Preparing

for Audits

With detailed lot tracking records, businesses can retrieve essential compliance data instantly, making audits smoother and more efficient.

Preventing Overstock

or Shortages

Overbuying leads to waste, while understocking causes delays and missed opportunities. Lot control software provides insights to balance stock levels and maintain supply chain efficiency.

Book a Free Demo With Our Consultant

See how FlexiBake’s lot tracking software can simplify compliance, enhance inventory management, and ensure food safety—all in one powerful system.

Book a Free Demo With Our Consultant

See how FlexiBake’s lot tracking software can simplify compliance, enhance inventory management, and ensure food safety—all in one powerful system.