Manufacturing Inventory Management Software

Food manufacturing businesses face various challenges beyond stocking shelves; precision, timing, and minimizing waste are crucial for success. The wrong purchasing calculation might result in production stops, low excess stock, or expensive emergency orders. FlexiBake’s manufacturing inventory management software streamlines procurement processes to match up with production requirements.

Automated purchasing and order management help manufacturers stay on schedule, manage supplier relationships, and streamline procurement—allowing production teams to focus on making great food.

|

Key Elements of the Inventory Ecosystem

A strong manufacturing inventory system is not just storage management — it’s how efficiently you coordinate your purchasing, storage, tracking, and organization. Here’s how those pieces fit together:

1 —

Ingredients Purchasing

Inventory management begins with procuring the appropriate raw materials on time. By automating purchasing, manufacturers are assured they’ll never run out of the essentials to feed the production schedule.

To keep production on track, manufacturers need the right raw ingredients at the right time. Automated purchasing helps ensure essentials like flour, dairy, and packaging are always in stock—preventing last-minute shortages and delays.

2 —

Food Warehouse Management System

Proper ingredient storage and organization are essential for inventory accuracy and food safety compliance. FlexiBake’s Food WMS enforces FIFO (First In, First Out), tracks ingredient locations, monitors expiration dates, and automates stock movements. With real-time insights, automated storage allocation, and barcode scanning, food manufacturers can prevent misplaced inventory, avoid expired batches, and optimize order fulfillment.

3 —

Cold Storage & Palletizing

Managing temperature-sensitive ingredients storage is crucial to prevent spoilage and maintain food safety standards. FlexiBake’s Cold Storage Software helps manufacturers manage frozen and chilled inventory, ensuring optimal storage conditions and efficient pallet organization. With real-time temperature tracking and inventory monitoring, manufacturers can easily maintain compliance.

4 —

Lot Tracking

Ingredient traceability and batch tracking are essential for compliance and quality control. FlexiBake’s Lot Tracking Software records every ingredient and finished product throughout production and distribution, ensuring full transparency and recall readiness. With lot-coded tags and detailed tracking, manufacturers can reduce waste, prevent contamination, and conduct recalls in under 10 seconds.

These elements are part of a comprehensive inventory and production management software solution that helps food manufacturers optimize workflows, minimize waste, and stay on track.

How FlexiBake Automates Purchasing & Order Management

Placing orders for ingredients in the right quantities and at the right time is critical to the success of your production process. FlexiBake takes the guesswork out by integrating supplier management, purchase order automation, and order receipt into one seamless process. Our features, such as manufacturing inventory control software and advanced production inventory management software, are designed to meet the specific needs of the food manufacturing industry.

Suppliers Management

FlexiBake centralizes supplier data, automates communication, and manages order approvals—helping you negotiate better prices, track productivity, and ensure a steady supply of raw materials without extra admin work.

Centralized

Supplier Database

FlexiBake keeps all your supplier information in one place, making it easy to manage. You can update lot numbers, costs, and quantities when receiving material from various suppliers. If you use a date stamp, auto-populate the date the material is received.

Supplier Price Comparison & Cost Control

Raw material prices fluctuate. When receiving raw materials, allow the preference to add on additional costs such as freight, taxes, and fuel charges. Distribute charges by either value, quantity, or weight to ensure accurate cost breakdown.

Automated Communication & Order Approvals

Automate purchasing, place and approve orders, and email suppliers directly from FlexiBake. Keep order processing smooth with precise tracking and timely confirmations.

Inventory Control

Accurate Order Tracking

Maintaining strong supplier relationships requires real-time order history tracking, delivery accuracy, and performance metrics. A centralized dashboard allows manufacturers to assess supplier reliability and make informed purchasing decisions.

Smart Inventory Planning

With a single click, generate reports on inventory levels, ingredient allocation, and materials on order. Use real-time data to analyze trends, make informed purchasing decisions, and immediately create purchase orders.

Automated Stock Replenishment

FlexiBake eliminates last-minute ingredient shortages by setting automatic reorder triggers. Track real-time inventory and usage trends to ensure a steady supply without overstocking.

Full Inventory Visibility

Excess leads to spoilage and shortages lead to delays. With all purchasing, inventory, and order details stored in a single ERP system, manufacturers have instant access to critical data, allowing for more informed planning and increased efficiency.

Purchase Orders

Managing purchase orders doesn’t have to be time-consuming. FlexiBake automates the entire ordering process, reducing manual work and maintaining inventory without over-ordering. With real-time tracking and automated approvals rules, you’ll always have the right ingredients on hand when you need them—without the headaches.

Auto-Generated POs Based on Inventory

Never run out of stock again. FlexiBake automatically generates purchase orders when the stock reaches a pre-defined level, ensuring a stable supply chain.

Tracking Open & Completed Orders

Monitor pending and received orders in real-time. Track expected delivery dates, flag delays, and hold suppliers accountable.

Custom Approval Workflows

Maintain control over purchasing with multi-level approval systems, ensuring that only authorized orders are processed.

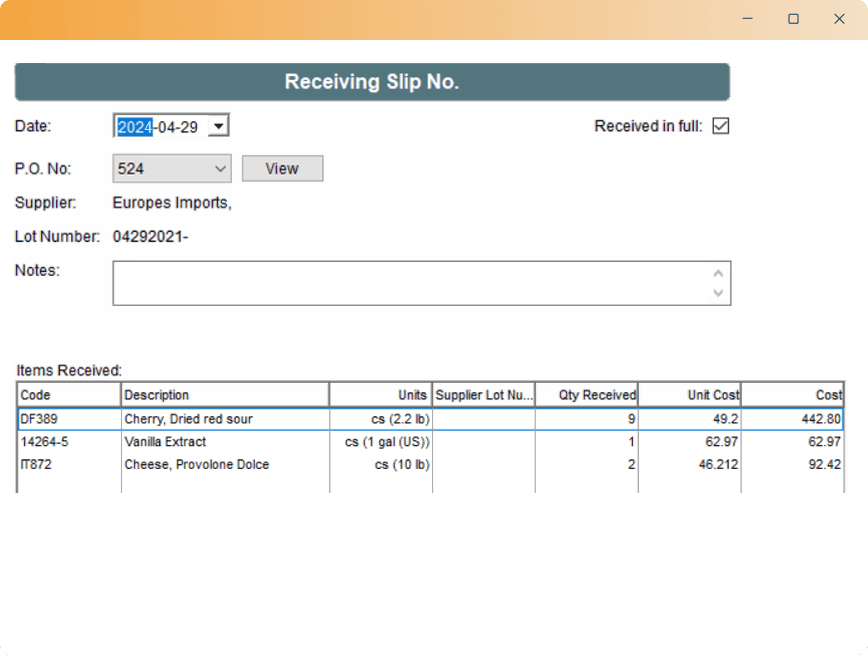

Receiving Orders

Loading your ingredients is just the first step. It’s just as essential to ensure they meet quality standards and are correctly tracked. FlexiBake streamlines the receiving process with automated quality checks, barcode scanning, and real-time inventory updates, so every delivery is accounted for, tracked, and ready for production the moment it arrives.

Automated Quality Checks on Delivery

Ensure ingredient quality by automating inspection processes at the point of delivery — reject substandard products before they enter production.

Integrated Barcode & Lot Tracking

Link incoming inventory directly to FlexiBake’s batch tracking system, ensuring full traceability from receipt to production.

Received Stock to Inventory Linking

The system automatically updates the system as soon as new stock arrives, allowing you to see ingredient availability in real-time.

Streamline Purchasing With FlexiBake

Eliminate pursuing suppliers and managing an excessive volume of emails. FlexiBake automates order requests, confirmations, and approvals, ensuring your supply chain is efficient and your production runs smoothly. Request a free consultation to see how easy purchasing and supplier management can be.