Production Planning & Scheduling Software

Poor scheduling and manual tracking often cause production delays, wasted materials, and compliance issues. A robust ERP system eliminates that, ensuring efficiency, accuracy, and complete visibility over operations.

With manufacturing production planning software, you can:

- Automate scheduling and eliminate bottlenecks

- Reduce errors with real-time data tracking

- Stay compliant with industry regulations

- Optimize resources and cut waste

- Ensure on-time production and delivery

- … and much more!

From small-batch orders to large-scale manufacturing, production scheduling software for manufacturing streamlines every step—keeping you on track without the stress.

Benefits of Production Management

An efficient production management system is more than keeping operations running—it optimizes, predicts, and adapts them. FlexiBake’s manufacturing production planning software helps manufacturers anticipate shifting demand, minimize errors, and easily make data-driven decisions.

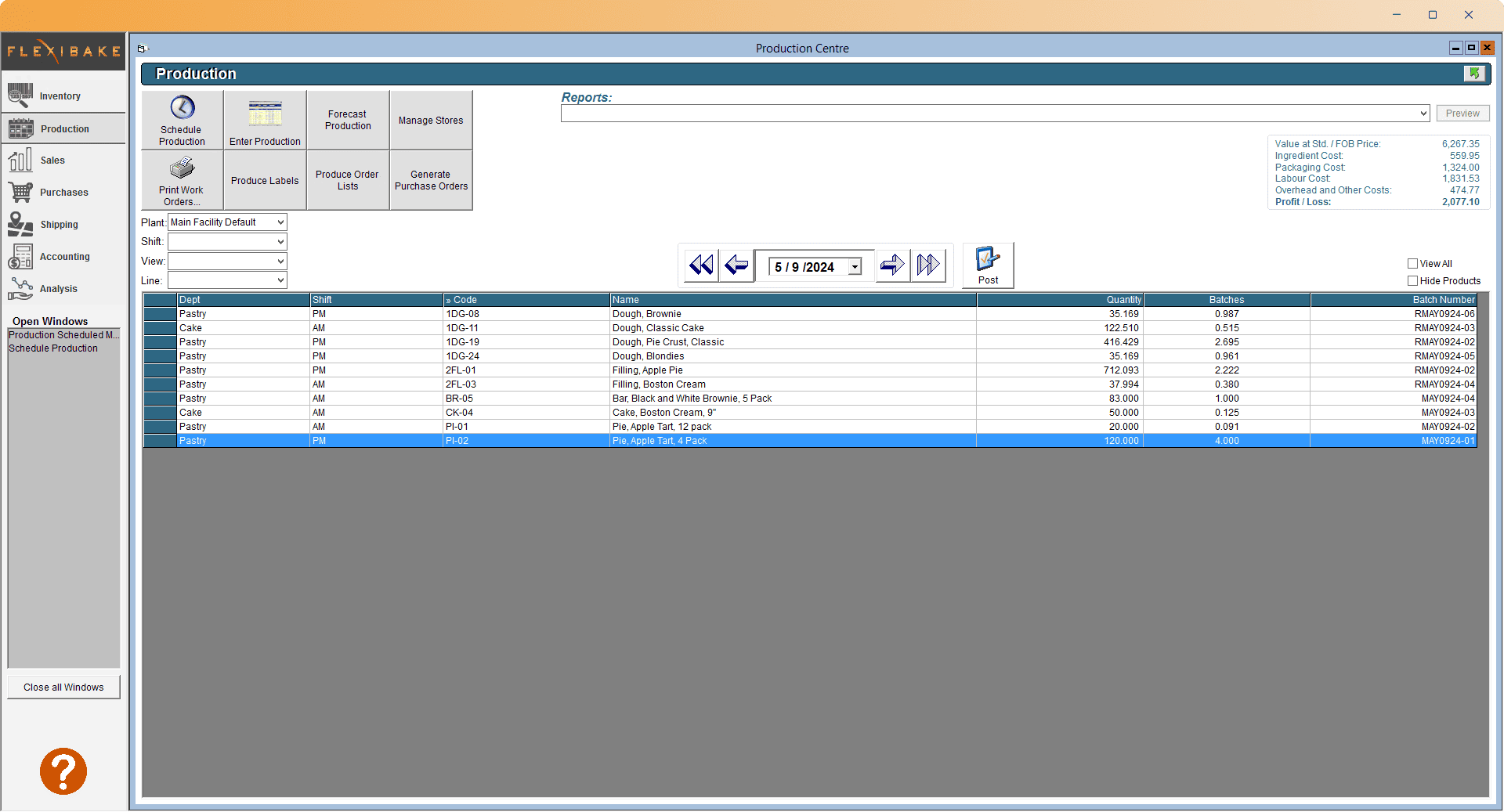

Run Multiple Reports With Real-Time Updates

- Monitor production changes instantly without waiting for manual updates

- Reduce human errors with automated tracking and reporting

- Respond faster to disruptions, material shortages, or unexpected demand shifts

With manufacturing production scheduling software, up-to-the-minute insights mean fewer delays and better decision-making—without the frustration of outdated spreadsheets.

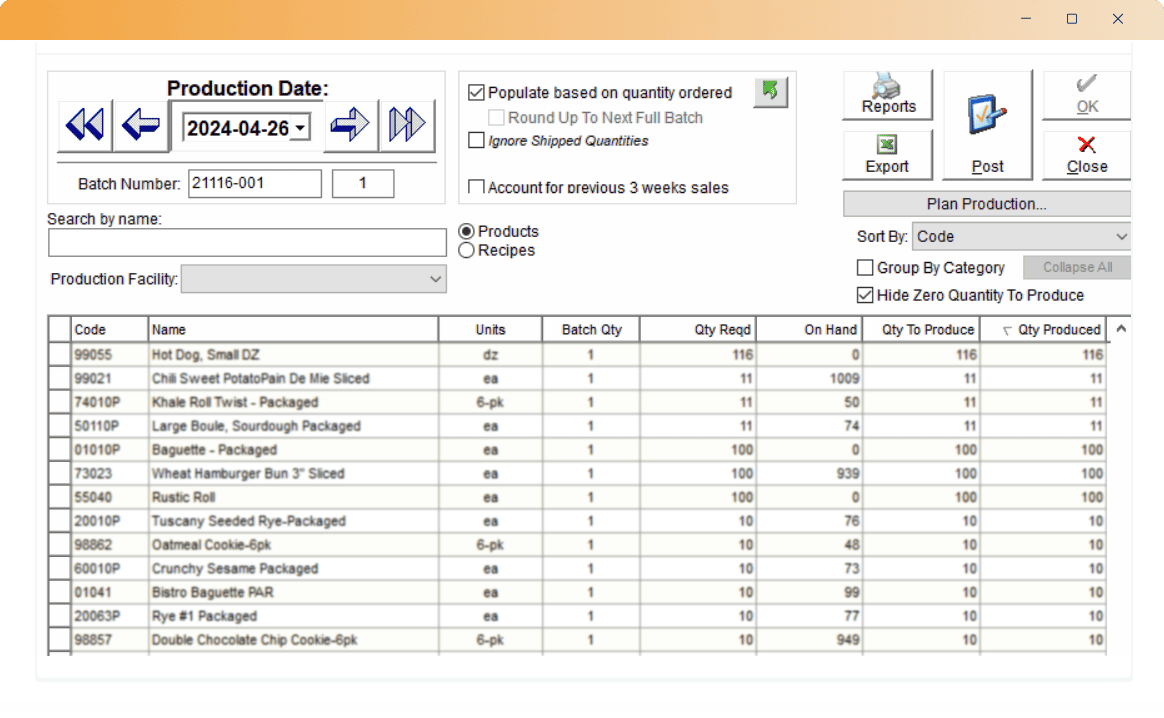

Manage Large Product Catalogs & Lead Times With Ease

- Streamline product scheduling for diverse product lines

- Track lead times to prevent shortages and avoid last-minute scrambling

- Adjust production plans on the fly to match actual demand

No more miscalculations, lost inventory, or missed deadlines—just smooth, organized workflows.

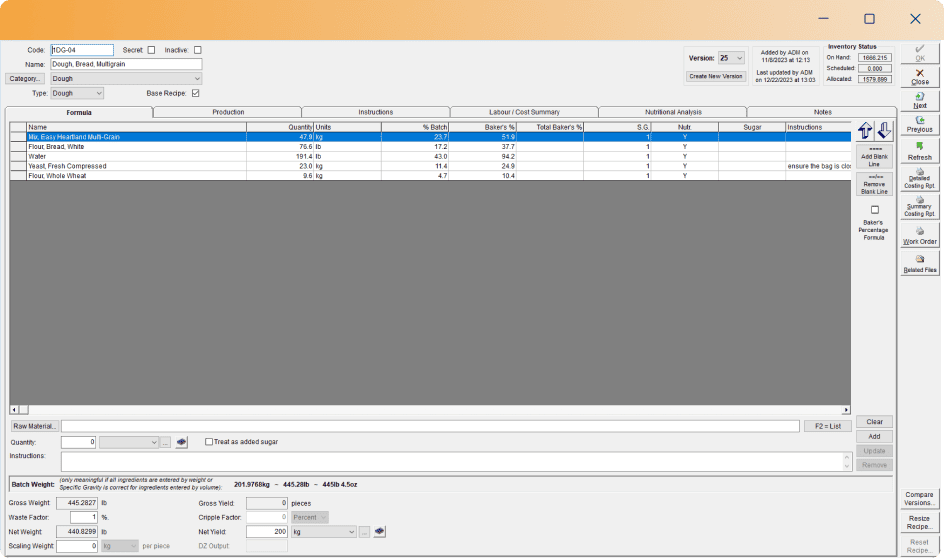

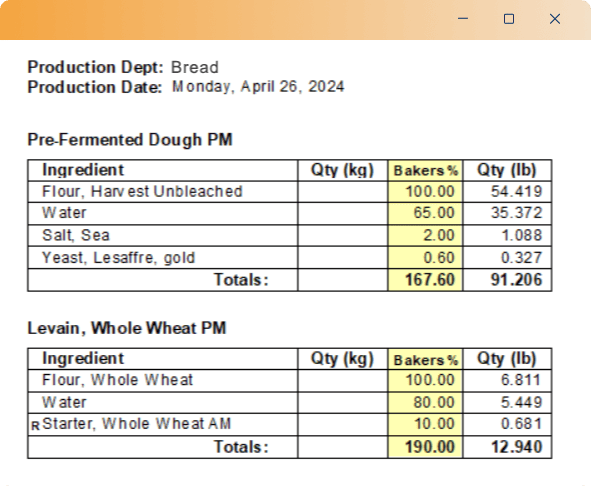

Complicated Recipes, Simplified

- Version control to track recipe adjustments

- Batch adjustments for real-time modifications

- Automatic ingredient calculations for consistent production

Production is simple when you link inventory to the recipe and include details such as waste percentages and special instructions.

Forecasting Tools Give You

a Competitive Edge

- Anticipate production needs based on historical and real-time data

- Minimize waste by aligning production with demand

- Optimize inventory levels to prevent overstocking or shortages

Intelligent forecasting means fewer last-minute surprises and more predictive profitability.

Optimize Resource Allocation & Minimize Waste

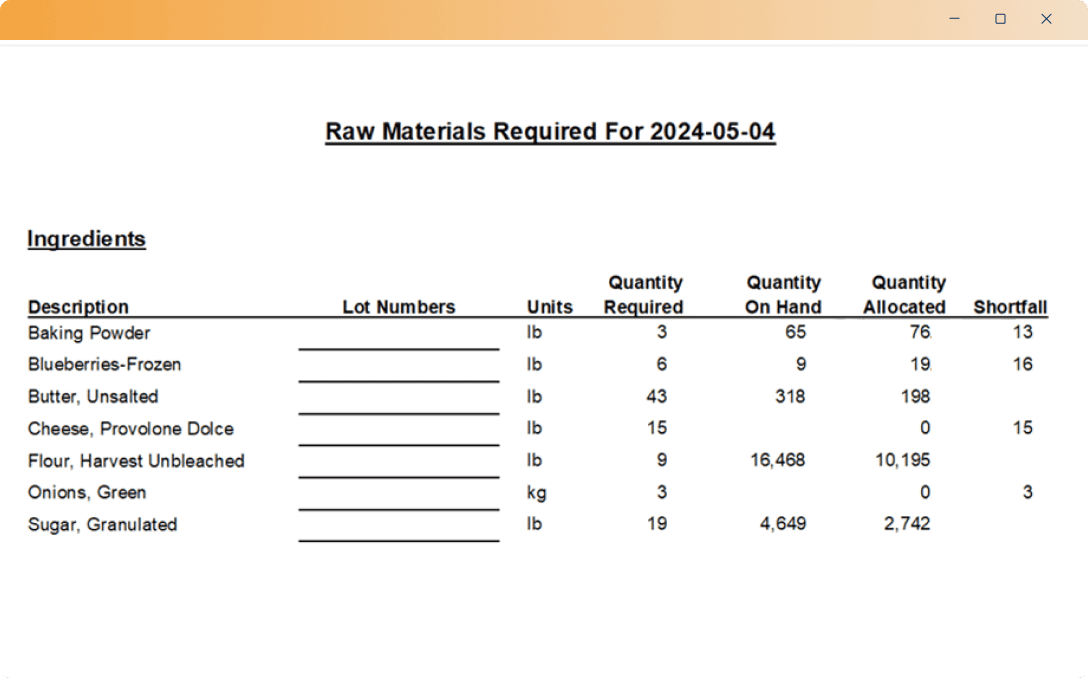

- Track raw materials and work-in-progress to prevent spoilage and excess inventory

- Allocate labor efficiently to avoid overtime and scheduling conflicts

- Monitor machine efficiency to reduce downtime and maximize output

A well-planned production process isn’t just about keeping things running—it’s about running smarter, faster, and cost-effectively.

Advantagesof Production Scheduling

With FlexiBake’s production scheduling software, manufacturers get assistance making every step more efficient, transparent, and compliant.

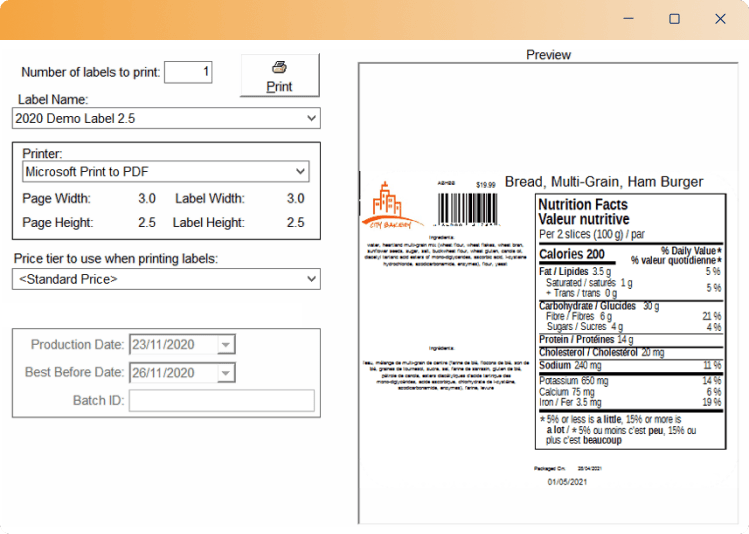

Integrated Label Designer for Full Traceability

- Create labels with UPC codes, nutritional facts, ingredient statements, lot numbers, expiration dates, and more.

- Ensure compliance with industry regulations and retail requirements

- Automate label generation to match production output

Every item, from raw materials to finished goods, is tracked, documented, and ready for distribution.

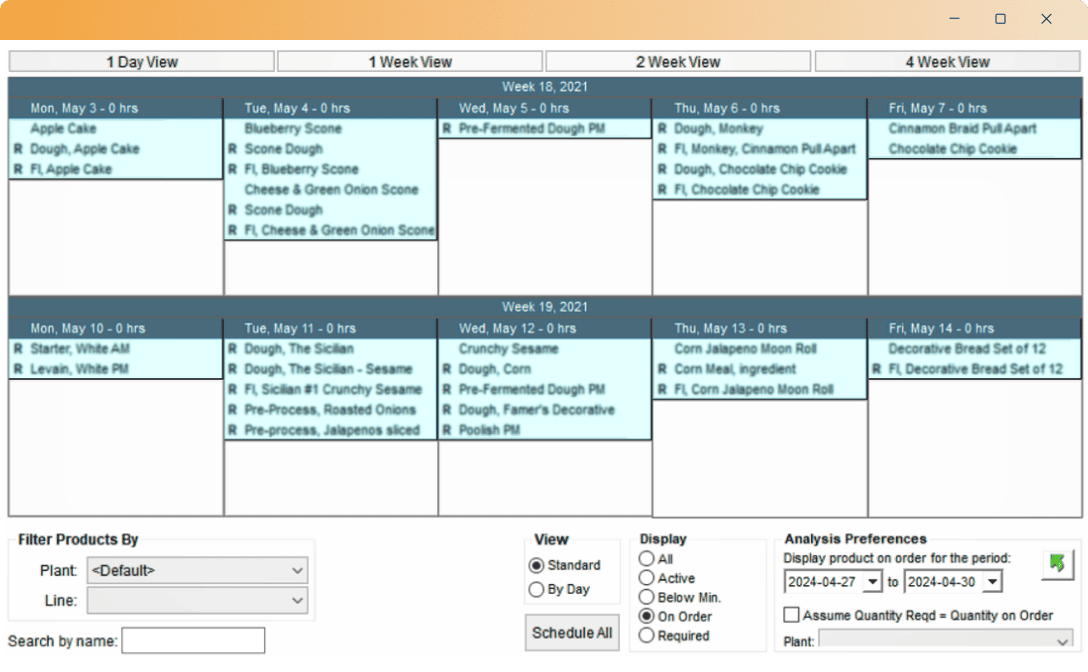

Drag-and-Drop Scheduling for Instant Adjustments

- Easily adjust production timelines with a simple drag-and-drop interface

- Prioritize urgent tasks to avoid bottlenecks

- Sync schedules in real-time across teams and departments

With built-in automation and live updates, your production stays on schedule—even when things change at the last minute.

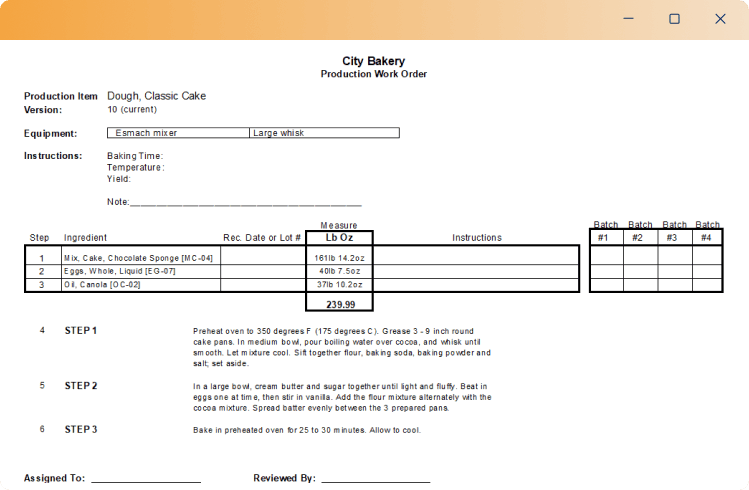

Effortless Reporting: BOMs, WIPs, Work Orders & Costs

- Create BOMs automatically to standardize production

- Generate work orders in one click to keep teams aligned

- Analyze costs and materials usage for better budgeting

All reports are stored in a centralized dashboard, making them easy to access when you need them.

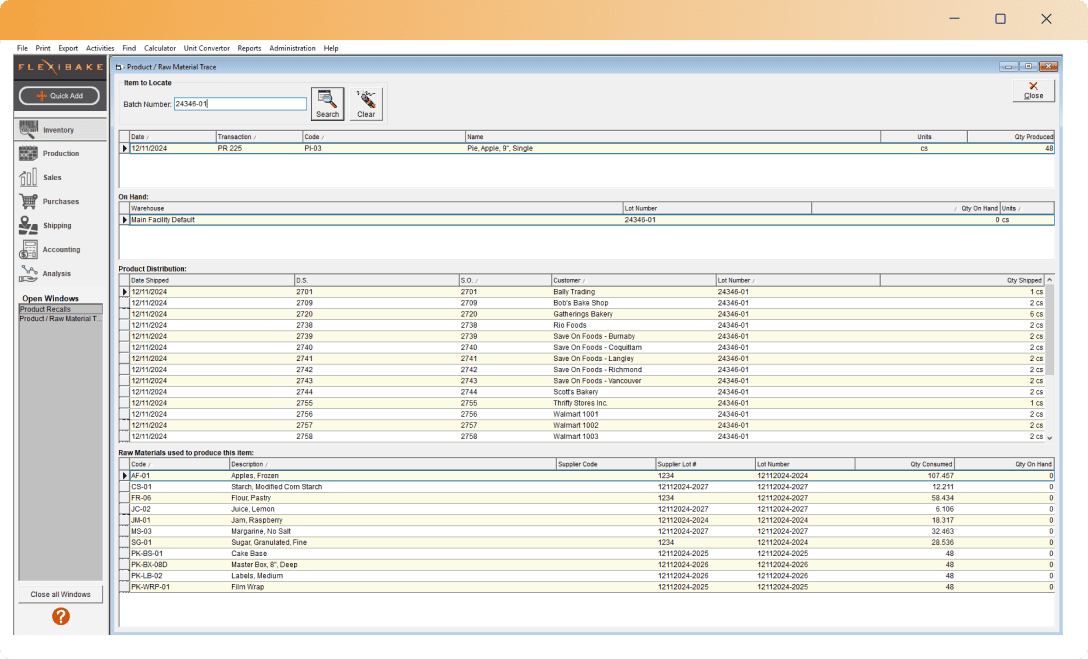

Instant Lot Tracking for Raw Materials, WIPs & Finished Products

- Tracks raw material and work-in-progress consumption in real-time

- Automatically updates inventory levels as production runs

- Links finished goods to lot numbers for complete traceability

Whether you’re facing an audit or tracing a batch issue, production planning software for manufacturing provides instant visibility.

Built-In Compliance

for HACCP, FSMA, BRC & More

- Automating reports for SQF, BRC, ISO, GFSI, CFIA, HACCP, FSMA, and BRC standards

- Ensuring full traceability from raw materials to distribution

- Providing real-time audit trails to meet industry requirements

With compliance built directly into production workflows, staying audit-ready has never been easier.

See How FlexiBake Simplifies Production

Automate production scheduling and eliminate bottlenecks

Improve traceability with real-time inventory and lot tracking

Ensure compliance with HACCP, FSMA, and BRC standards

Simplify reporting with built-in BOMs, work orders, and cost analysis

Let’s make your production process faster, smarter, and stress-free.