Scaling Your Bakery: A Strategic Approach to Wholesale Expansion

Improve Food Production With Smart Automation

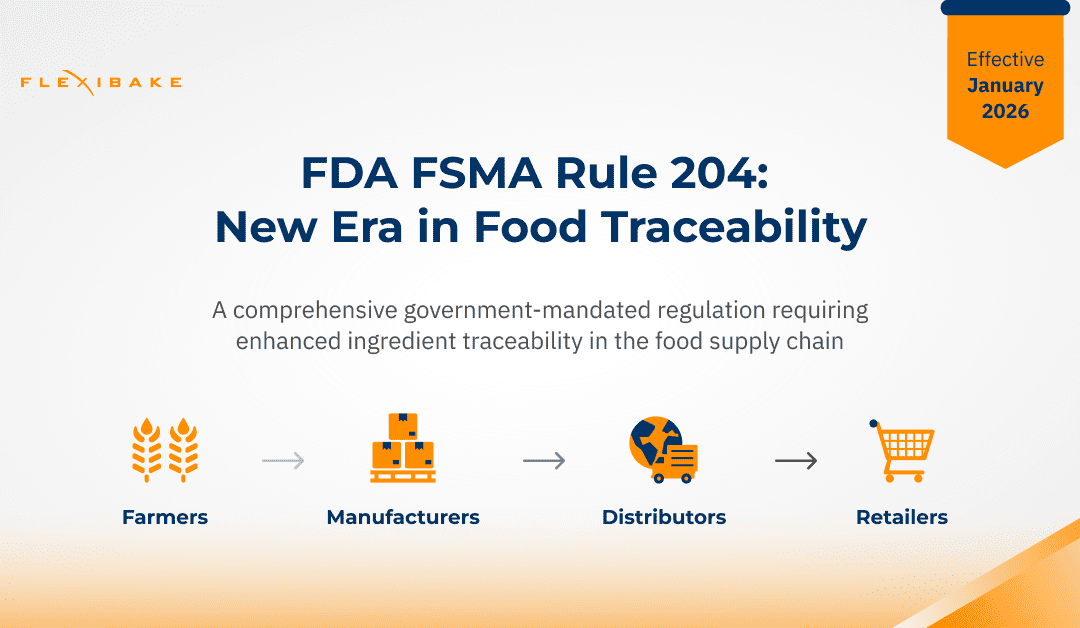

FDA FSMA Rule 204 Takes Effect January 2026: Critical Changes in Food Traceability

4 Key Features of FlexiBake

FlexiBake’s Essential Role in Accurate Costing

The Power of Sales Forecasting with FlexiBake

Boost Your Cookie Business with the Best Production Software

FlexiBake Simplifies Accounting with QuickBooks Integration